Bearings with a constant cross section, such those found in thin section bearings, may save a lot of space and lighten the load on the whole system. These are two considerations that should be made while making items with complicated and crucial applications. Cross section, which is normally square, is preserved even in bearings with huge bore diameters. Thin section bearings are typically employed when space limits or certain design configurations preclude the use of conventional bearings. When traditional bearings can’t be utilised due to factors like limited space or a particular design arrangement, engineers will typically turn to thinner sections of bearings.

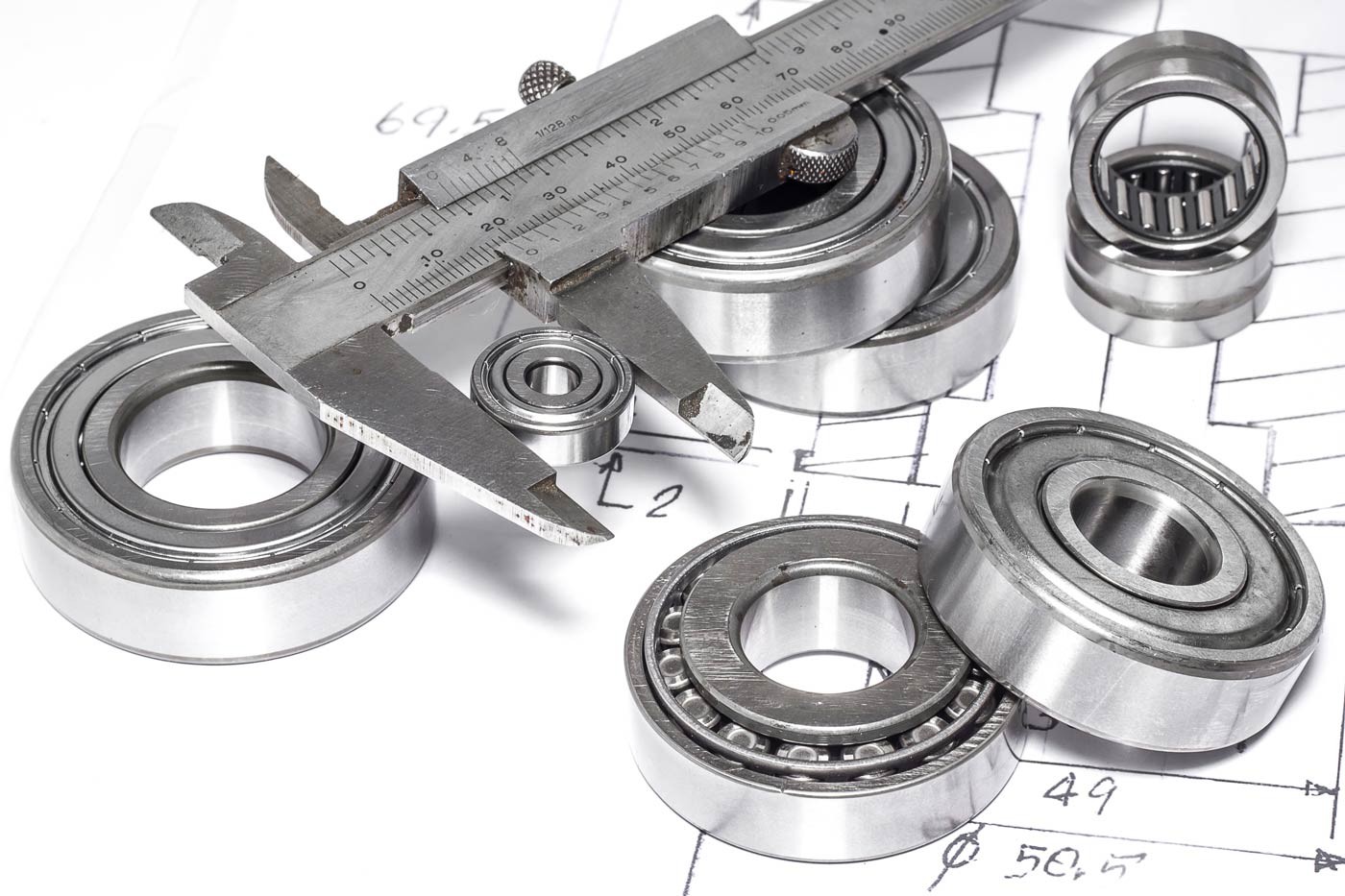

Small bearings that employ balls as its rolling element are known as miniature ball bearings. Miniature refers to the size of these bearings. Miniature precision bearings find widespread usage in fields as disparate as medicine, instrumentation, and semiconductors because of their ability to reduce friction between moving parts and maximise efficiency in confined spaces. The balls may be ordered in a range of sizes to meet the needs of any given undertaking.

The extraordinary design benefits afforded by thin bearings and micro ball bearings are regularly put to use in robotics and other significant fields of application.

Thin-section bearings are often used in a variety of industries.

Unlike most miniture bearing, the cross diameter of a thin section bearing is independent of the bore size. Therefore, it’s possible that the system’s price may be lowered and its general design can be simplified. Because of their compact size and low weight, these robots are widely used in a variety of robotic fields, including human assistance, pick and place, semiconductor, and medical.

High-tech applications may need custom bearings with unusual materials, surface coatings, or lubricants to fulfil the requirements of the equipment in question. Thin section bearings may effectively meet the needs of applications requiring, for example, very low or uniform torque, very high positioning accuracy, resistance to corrosion, and compatibility with very clean environments. Thin section bearings are used in camera setups because their light weight makes them ideal for applications where rigidity and stability are paramount.

The Challenges of Miniaturization

Micro bearings have many potential uses, but they may be difficult to maintain and adaptable in a variety of ways; the smaller the bearing, the more important it is to be mindful of these challenges. Beginning with regular maintenance is essential for the system’s long-term viability and efficiency. This may be accomplished by the use of regular lubrication or self-lubricating bearings.

Furthermore, there may be limited size and capacity options for micro bearings, which might be problematic for high-load applications. It’s important to be sure the company you partner with can provide the bearings or modification services you need if your application calls for a wide range of sizes.

However, depending on the application, the use of small bearings might render design changes difficult. No matter what you need corrosion-resistant coatings, ceramic balls, or interchangeable parts—you should be able to find a supplier to meet your needs.

Check It Out

Many industries, from medicine and robotics to high technology, may benefit from the unique features offered by miniature and thin section bearings. Compared to conventional bearings, these ones are compact, lightweight, and versatile.