With greater and greater amounts of businesses, industries, offices, and households digitizing their methods of operation, the demand for stronger and faster methods of computing is also skyrocketing. Cutting edge hardware aside, the performance of the computers and other electronic systems in a workplace is limited by the amount of internet bandwidth available to them. Normal LAN setups of Ethernet cables are not adequate to handle the huge amount of workload that is generated by some industrial projects. To fill this gap, this is where Industrial Ethernet comes in.

What is Industrial Ethernet?

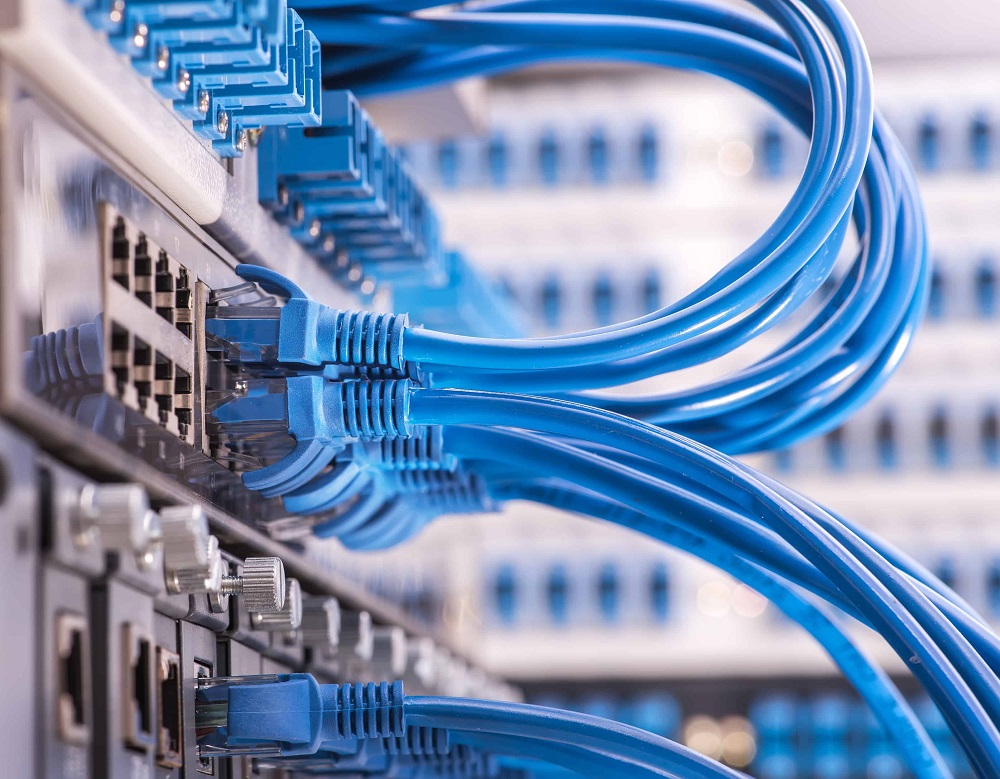

Industrial Ethernet is a form of Ethernet connectivity that is adapted to a very large scale and can handle substantially greater volumes of data. The biggest problem is that the TCP/IP Ethernet protocol that is commonly used cannot harness the full potential of the Ethernet cables. This means that even though the Ethernet hardware is capable of seamless and real time digital communication, the software holds it back from being useful for machinery and industrial applications. Industrial Ethernet is built on this premise to deliver real time control and determinism in performance. This is achieved by building a modified protocol and application layer for the same Ethernet hardware. This application layer is often proprietary and tailored to individual business needs.

Benefits of Industrial Ethernet:

- Lowering of latency allows smoother and seamless data transfer.

- Industrial Ethernet can handle greater bulks of data and is suited for large industries and organizations.

- Real time control allows fine motor operation of heavy operation.

- Determinism or guarantee ensures that the industrial machinery keeps on working and there is no lag in the digital communication between systems.

- Reduced risks of internet security threats on an industrial network.

- Due to more rugged and high quality hardware, industrial Ethernet can operate in harsher, more taxing environments.

Popular Industrial Ethernet Protocols:

- Modbus TCP/IP: First industrial Ethernet, a very simple modification of normal Ethernet.

- EtherCAT: Was created in 2003 and allows communication on the fly between master and slave systems.

- Ethernet/IP: Created in 2000 by Open Device Vendors Association and Rockwell Automation. Largely based on standard Ethernet Protocols.

- PROFINET: Developed by Siemens, it is often used by Siemens’ own systems and GE.

Opting into Industrial Ethernet is sensible only for large industrial business that has big budgets and special performance needs for their machinery.