Laser cutting, marking, and etching have revolutionized manufacturing and production processes. However, these processes release harmful fumes and particulates that can compromise air quality and worker health. Implementing a robust laser cutter extraction system is essential for reducing workplace air contaminants. These systems not only protect employees but also ensure compliance with occupational health and safety standards.

Understanding the Hazards of Laser Cutting

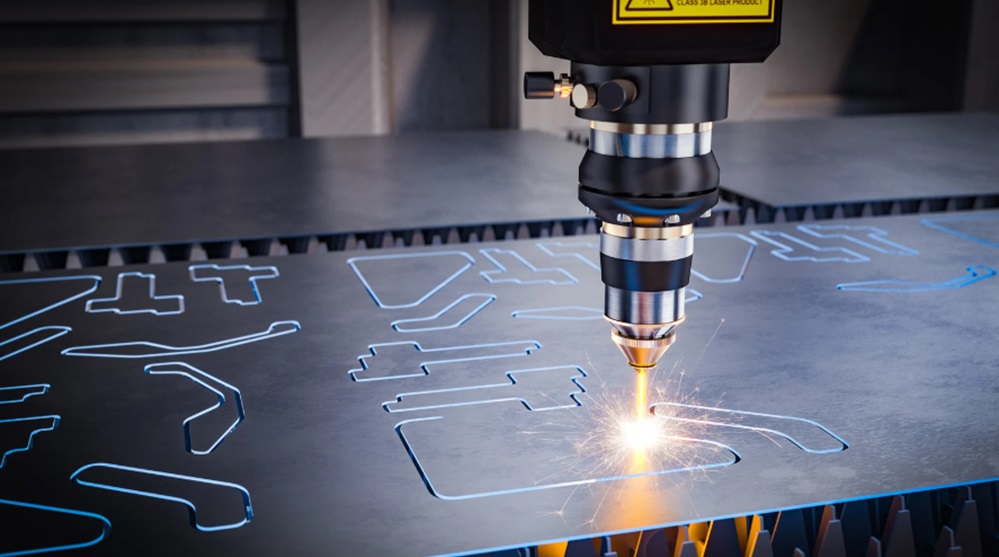

Laser cutting involves intense heat that burns through materials like wood, plastic, and metal. This process generates fine dust, fumes, and volatile organic compounds (VOCs), which can be hazardous when inhaled. Even short-term exposure to such contaminants can cause coughing, irritation, or headaches. Long-term exposure increases the risk of respiratory illnesses and other health issues, making air filtration an absolute necessity.

The Importance of Choosing a Reliable Fume Extractor

To combat these risks effectively, it’s crucial to invest in a high-performance extraction system. Choosing a laser fume extractor depends on various factors, such as the type of laser system, the material being processed, and the volume of fumes generated. Advanced systems come equipped with filtration technologies like HEPA and activated carbon filters, which can capture fine particles and neutralize harmful fumes before they circulate in the workspace.

A well-chosen fume extractor is not only an investment in the safety of employees but also enhances equipment longevity by reducing the buildup of fumes on machines. This ensures uninterrupted operations and significant cost savings in maintenance over time.

Risks of Ignoring Proper Fume Extraction

Neglecting fume extraction systems can lead to serious repercussions for both health and productivity in the workplace. Studies have shown that laser cutting risks without fume extractors include reduced lung function, increased chances of respiratory diseases, and even chemical burns from exposure to certain materials. Beyond individual health, businesses may also face regulatory penalties for failing to meet air quality standards, leading to financial and reputational damage.

Furthermore, unfiltered fumes can settle on equipment and surfaces, creating a potential fire hazard and increasing cleaning requirements. This highlights the indispensable role of professional-grade fume extraction systems in ensuring safety and regulatory compliance.

Key Benefits of Laser Fume Extraction Systems

Investing in laser fume extraction offers numerous benefits. These systems improve workplace air quality by efficiently removing harmful emissions at the source. Cleaner air enhances employee well-being, leading to increased focus and productivity. Additionally, proper filtration prevents fumes from accumulating on sensitive equipment, reducing downtime and extending the lifespan of machinery.

Advanced laser fume extraction systems also incorporate user-friendly features such as real-time monitoring and energy-efficient filters. These systems are designed for optimal performance, offering businesses an effective long-term solution to workplace air contamination challenges.

Conclusion

Prioritizing employee safety and environmental responsibility should be integral to every organization’s operations. Professional laser fume extraction systems address these aspects by filtering out harmful contaminants, sustaining optimal air quality, and adhering to safety regulations. Rather than relying on inadequate or improvised solutions, businesses must partner with professionals to design and install the right extraction systems tailored to their specific needs.

By taking these preventive measures, companies can ensure the health of their workforce, maintain operational efficiency, and create a safer and cleaner workspace. Investing in professional-grade laser cutter extraction technology is not just a regulatory requirement but a commitment to long-term success.