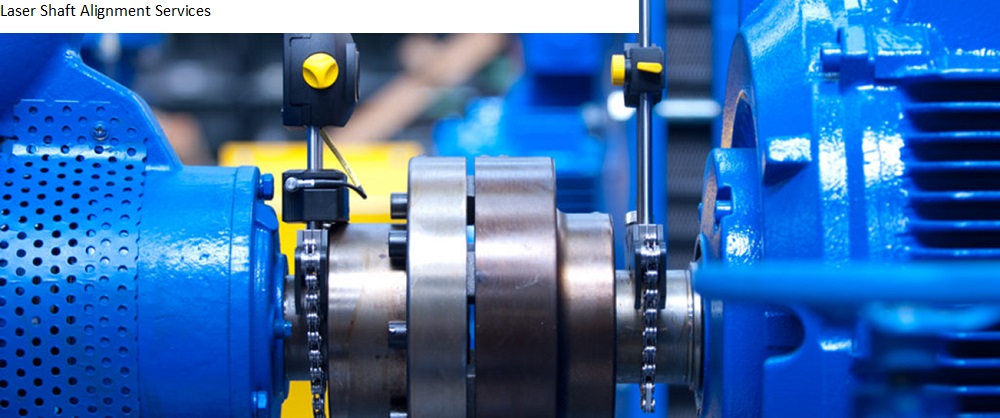

Laser shaft alignment is an essential service to take on or toolset to own to ensure all your moving parts and machines are running at an optimum level. With professional solutions on hand, you can correctly and accurately assess machine elements to ensure that the components are lined up and not causing friction damage. Then, when you have the right experts to guide you, you can get the best systems to ensure all your assets are running in perfect condition. There is far more chance of human error with manual methods, while with these technologically advanced alternatives, you can rely on precise electronic data. Read on to find out more about using these systems to your advantage.

Early Identification Of Issues

Early identification of problems enables machine maintenance to be proactive and catch any issue long before it causes damage. As an accident or breakdown can result in any range of downtime, having your assets running incorrect order is the best way to ensure your business maintains operations. Whether dealing with industrial settings, commercial stores or any other industry, your machines need to be supported and aligned when dealing with moving shaft parts. Early identification of small movements or shifts allows you to accurately and effectively correct the misalignment before it becomes an issue.

Reduce Costs Of Maintenance

Maintenance costs can account for many draws on the corporate budget, especially when working within the mining or similar industrial sectors. These large machines need to run in perfect order or risk shutting down the entire operational line. When you use alignment tools that can accurately implement needed adjustments to shafts and mechanisms before they cause damage to the surrounding machine parts, reduced maintenance costs as a result of sharp reductions in bearing, seal, rod, and coupling failures can help you bolster your business and ensure money is being spent more advantageously.

Reduce Vibrations

Vibrations within the working space can signify bad things happening behind the scenes. These slight movements often worsen over time and are a clear sign of moving components hitting or rubbing against each other. Reduced vibrations lengthen the useful lifecycle of the machines and increase the quality of the results the machines can produce. On the other hand, these vibrations can lead to drastic results and breakdowns that will hamper your ability to operate as you need. Reducing vibrations ensures a safer workspace and the longevity of machines you need to work on.

Lower Downtime

Less unplanned downtime means that production can be optimized at all times. Maintenance and repair take time, but far more time is lost when dealing with a serious breakdown of machine components. This damage usually means time wasted to fix it and potentially wait for parts to be flown in. This delay can cost you money and potential clients as you sit at a standstill until repairs have been made. When you regularly check the alignment of machine parts, you can use in-depth data to analyze the setup and ensure all details are running ideally. Lowering downtime should be a top priority when you provide the smooth running of your business.

Accurate Measuring

Error-free and accurate measurements are key to perfect alignment. This accuracy cannot be achieved with manual methods as there is more room for human error and more simple tools. With the laser system, you can find, with pinpoint accuracy, the level of misalignment and to what degree the system is off. More accurate data ensures far more accurate results that keep your machine operating at optimum levels.

Laser shaft alignment services can help you maintain the integrity and longevity of your machines and operations throughout the year. These solutions ensure that all moving parts are operating as intended and nothing is causing undue damage to the internal component of the machines. Contact us today to find out more about these solutions.